Rotary joints for non-destructive testing (NDT) applications, designed for data and power transmission during inspections

Non-destructive material testing (NDT) refers to a set of techniques used to evaluate the properties and integrity of materials or structures without causing damage or permanent alteration to them. The purpose of NDT is to identify defects, flaws, or irregularities that may affect the performance, safety, or reliability of the material or component being tested.

Non-destructive testing methods involve the use of various physical principles, such as sound waves, electromagnetic radiation, thermal energy, and mechanical vibrations, to inspect and analyze the internal and surface characteristics of materials. These methods can detect defects such as cracks, voids, inclusions, discontinuities, corrosion, and structural abnormalities.

The key aspect of non-destructive testing is that it allows inspection and assessment of materials or structures while keeping them intact and functional. This is particularly beneficial for critical components, expensive materials, or structures where destructive testing would be impractical, costly, or impossible.

Common techniques used in non-destructive testing include:

- Ultrasonic Testing (UT): Utilizes high-frequency sound waves to detect internal flaws or measure material thickness.

- Radiographic Testing (RT): Involves the use of X-rays or gamma rays to examine the internal structure of objects.

- Magnetic Particle Testing (MT): Detects surface or near-surface defects in ferromagnetic materials by applying a magnetic field and using magnetic particles.

- Liquid Penetrant Testing (PT): Uses a liquid dye or fluorescent solution to identify surface-breaking defects.

- Eddy Current Testing (ECT): Detects surface or near-surface flaws by inducing electrical currents in conductive materials and analyzing changes in the current flow.

- Thermographic Testing (TT): Utilizes infrared thermography to detect variations in surface temperature and identify anomalies.

- Visual Testing (VT): A basic method involving direct visual inspection to identify surface defects.

These techniques, along with others, are employed in different industries such as manufacturing, aerospace, automotive, construction, and energy, to ensure the quality and reliability of materials, components, and structures while avoiding unnecessary damage.

Rotary joints can be utilized in non-destructive testing (NDT) applications to enable the transmission of both data and power between stationary and rotating components. In NDT, rotary joints are commonly employed when the testing equipment requires a continuous rotation or movement while maintaining a connection to external data and power sources.

The specific design and implementation of rotary joints will depend on the equipment used, the desired rotation range, and the required data and power transmission specifications for each NDT method. Rotary joints are crucial components that facilitate the seamless transfer of signals and power between stationary and rotating elements, enabling efficient and effective NDT inspections.

Rotary joints are engineered with a focus on delivering exceptional performance and ensuring seamless connectivity

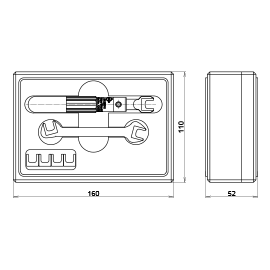

Introducing our state-of-the-art rotary joints for non-destructive testing (NDT) applications, designed to optimize data and power transmission during inspections. Our rotary joints are engineered with a focus on delivering exceptional performance and ensuring seamless connectivity between stationary and rotating components.

- Unparalleled Data Transmission: With our rotary joints, you can achieve uninterrupted data transmission during dynamic NDT processes. Say goodbye to signal loss or disruptions, and embrace a new level of reliability in your inspections.

- Reliable Power Supply: Powering your NDT equipment during rotation is no longer a challenge with our rotary joints. We understand the criticality of uninterrupted power supply, which is why our rotary joints are designed to ensure continuous electrical power transmission. Experience consistent and reliable performance, eliminating power disruptions that could compromise the effectiveness of your tests.

- Seamless Integration: Our rotary joints are engineered for effortless integration into your existing NDT systems. With their compact design and user-friendly installation process, you can quickly incorporate our rotary joints into your equipment, minimizing downtime and maximizing productivity. Seamlessly connect your stationary and rotating components with confidence, knowing that our rotary joints will deliver optimum performance.

- Robust and Durable: Built to withstand the demands of rigorous NDT applications, our rotary joints are constructed with robust materials and precision engineering. They are meticulously crafted to endure harsh conditions, ensuring longevity and durability. Rely on our rotary joints to consistently deliver exceptional results, test after test, without compromising on quality.

- Enhance Your NDT Capabilities: By utilizing our rotary joints, you can elevate your NDT capabilities to new heights. Experience smoother inspections, improved data accuracy, and enhanced efficiency, enabling you to identify defects and irregularities with greater precision. Unlock the full potential of your NDT processes with our advanced rotary joint solutions.

Trust in our Rotary Joints: Our rotary joints have been trusted by NDT professionals worldwide, offering unparalleled performance and reliability. Join the ranks of satisfied customers who have elevated their non-destructive testing capabilities with our cutting-edge technology. Experience peace of mind knowing that our rotary joints are designed to deliver exceptional results every time.

Take your NDT inspections to the next level with our data and power transmission rotary joints. Contact us today to discover how our innovative solutions can transform your NDT processes and empower you to achieve superior results.

Partner with the Experts

Our team of experienced engineers and industry experts is dedicated to delivering state-of-the-art solutions tailored to your unique needs. We prioritize durability, reliability, and compliance with stringent safety standards, ensuring your complete peace of mind. With our comprehensive support and superior products, you can confidently create captivating fun rides that surpass expectations.

Don't settle for less when it comes to data or power transmission in fun rides. Experience the power, precision, and seamless connectivity of our rotating solutions. Join the ranks of leading technical engineers who trust our solutions to deliver extraordinary experiences. Contact us today to embark on a new era of non-destructive testing applications.

- High performance: SPINNER rotary joints offer low insertion loss or excellent VSWR (Voltage Standing Wave Ratio) performance, ensuring reliable transfer of electrical power, radiofrequency or optical signals with minimal power loss or signal distortion.

- Durability and reliability: SPINNER rotary joints are designed and manufactured to withstand harsh environmental conditions, which includes exposure to dust, moisture, saltwater corrosion or high temperatures, and frequent use, ensuring reliable and long-lasting performance. They are designed to withstand the constant rotation and the stresses associated with non-destructive testing

- Minimal maintenance requirements: SPINNER rotary joints require minimal maintenance and are designed for easy repair and replacement, reducing downtime and maintenance costs.

- Wide range of options: SPINNER offers a wide range of rotary joint options, including different sizes, frequencies, technologies and (rf, fiber optics, Ethernet, …) and power handling capabilities, allowing for greater customization and flexibility in design.

- Integration with automation systems: SPINNER rotary joints can be integrated with automation systems for remote monitoring and control, allowing for more efficient and streamlined operations.

SPINNER rotary joints offer several advantages, including a wider range of options, higher electrical performance, and better durability and reliability. Additionally, SPINNER's focus on customization and flexibility allows for more tailored solutions to meet the specific needs of non-destructive testing applications.